設計標準

? 技術規范:德標

? 設計標準:DIN3357

? 結構長度:DIN3202

? 連接法蘭:DIN2542-2546

? 試驗與檢驗:DIN3230

? 公稱壓力:1.6、2.5、4.0、6.3 Mpa

? 強度試驗:2.4、3.8、6.0、9.5Mpa

? 密封試驗:1.8、2.8、4.4、7.0Mpa

? 氣密封試驗:0.6Mpa

? 閥門主體材料:WCB (C), CF8 (P), CF3 (PL), CF8M (R), CF3M (RL)

? 適用介質:水、蒸汽、油品、硝酸類、醋酸類

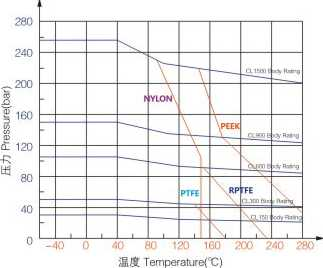

? 適用溫度:-29°C-150° C

產品概覽

德標球閥采用分體式結構設計,密封性能好,不受安裝方向限制,介質流動可任意;球體與球體之間有防靜電裝置;閥桿防爆設計;自動壓縮填料設計,流體阻力小;日標球閥本身結構緊湊,密封可靠,結構簡單,維修方便,密封面和球面常處于關閉狀態,不易被介質沖蝕,操作維修方便,適用于水、溶劑、酸類和氣體等一般工作介質,如日標球閥,也適用于氧氣、雙氧水、甲烷、乙烯等介質工況,廣泛應用于各行業。

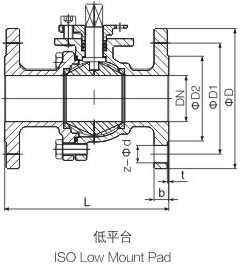

產品結構

主要零件材料

材料名稱 | 碳鋼 | 不銹鋼 | |

| 閥體 | WCB、A105 | CF8、CF3 | CF8M、CF3M |

| 閥蓋 | WCB、A105 | CF8、CF3 | CF8M、CF3M |

| 球體 | 304 | 304 | 316 |

| 閥桿 | 304 | 304 | 316 |

| 閥座 | 聚四氟乙烯。聚四氟乙烯 | ||

| 填料 | 聚四氟乙烯/柔性石墨 | ||

| 壓蓋 | WCB、A105 | CF8 | |

主要外形尺寸和連接尺寸

(DIN): PN1.6Mpa

DN | L | D | D1 | D2 | B | T | Z-ΦD | ISO5211 | TXT |

15 | 115 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | F03/F04 | 9X9 |

20 | 120 | 105 | 75 | 58 | 18 | 2 | 4-Φ14 | F03/F04 | 9X9 |

25 | 125 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 | F04/F05 | 11X11 |

32 | 130 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 | F04/F05 | 11X11 |

40 | 140 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 | F05/F07 | 14X14 |

50 | 150 | 165 | 125 | 102 | 18 | 3 | 4-Φ18 | F05/F07 | 14X14 |

65 | 170 | 185 | 145 | 122 | 18 | 3 | 8-Φ18 | F07 | 14X14 |

80 | 180 | 200 | 160 | 138 | 20 | 3 | 8-Φ18 | F07/F10 | 17X17 |

100 | 190 | 220 | 180 | 158 | 20 | 3 | 8-Φ18 | F07/F10 | 22X22 |

125 | 325 | 250 | 210 | 188 | 22 | 3 | 8-Φ18 | ||

150 | 350 | 285 | 240 | 212 | 22 | 3 | 8-Φ22 | ||

200 | 400 | 340 | 295 | 268 | 24 | 3 | 12-Φ22 | ||

250 | 450 | 405 | 355 | 320 | 26 | 3 | 12-Φ26 | ||

300 | 500 | 460 | 410 | 378 | 28 | 4 | 12-Φ26 |

(DIN): PN2.5Mpa

DN | L | D | D1 | D2 | B | T | Z-ΦD | ISO5211 | TXT |

15 | 115 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | F03/F04 | 9X9 |

20 | 120 | 105 | 75 | 58 | 18 | 2 | 4-Φ14 | F03/F04 | 9X9 |

25 | 125 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 | F04/F05 | 11X11 |

32 | 130 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 | F04/F05 | 11X11 |

40 | 140 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 | F05/F07 | 14X14 |

50 | 150 | 165 | 125 | 102 | 20 | 3 | 4-Φ18 | F05/F07 | 14X14 |

65 | 170 | 185 | 145 | 122 | 22 | 3 | 8-Φ18 | F07 | 14X14 |

80 | 180 | 200 | 160 | 138 | 24 | 3 | 8-Φ18 | F07/F10 | 17X17 |

100 | 190 | 235 | 190 | 162 | 24 | 3 | 8-Φ22 | F07/F10 | 22X22 |

125 | 325 | 270 | 220 | 188 | 26 | 3 | 8-Φ26 | ||

150 | 350 | 300 | 250 | 218 | 28 | 3 | 8-Φ26 | ||

200 | 400 | 360 | 310 | 278 | 30 | 3 | 12-Φ26 | ||

250 | 450 | 425 | 370 | 335 | 32 | 3 | 12-Φ30 | ||

300 | 500 | 485 | 430 | 395 | 34 | 4 | 16-Φ30 |

(DIN): PN4.0Mpa

DN | L | D | D1 | D2 | B | T | Z-ΦD |

15 | 115 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 |

20 | 120 | 105 | 75 | 58 | 18 | 2 | 4-Φ14 |

25 | 125 | 115 | 85 | 68 | 18 | 2 | 4-Φ14 |

32 | 130 | 140 | 100 | 78 | 18 | 2 | 4-Φ18 |

40 | 140 | 150 | 110 | 88 | 18 | 3 | 4-Φ18 |

50 | 150 | 165 | 125 | 102 | 20 | 3 | 4-Φ18 |

65 | 170 | 185 | 145 | 122 | 22 | 3 | 8-Φ18 |

80 | 180 | 200 | 160 | 138 | 24 | 3 | 8-Φ18 |

100 | 190 | 235 | 190 | 162 | 24 | 3 | 8-Φ22 |

125 | 325 | 270 | 220 | 188 | 26 | 3 | 8-Φ26 |

150 | 350 | 300 | 250 | 218 | 28 | 3 | 8-Φ26 |

200 | 400 | 375 | 320 | 285 | 34 | 3 | 12-Φ30 |

250 | 450 | 450 | 385 | 345 | 38 | 3 | 12-Φ33 |

300 | 500 | 515 | 450 | 410 | 42 | 4 | 16-Φ33 |

(DIN): PN6.3Mpa

DN | L | D | D1 | D2 | B | T | Z-ΦD |

15 | 140 | 105 | 75 | 45 | 20 | 2 | 4-Φ14 |

20 | 152 | 130 | 90 | 58 | 22 | 2 | 4-Φ18 |

25 | 165 | 140 | 100 | 68 | 24 | 2 | 4-Φ18 |

32 | 178 | 155 | 110 | 75 | 26 | 2 | 4-Φ22 |

40 | 190 | 170 | 125 | 88 | 28 | 3 | 4-Φ22 |

50 | 216 | 180 | 135 | 102 | 26 | 3 | 4-Φ22 |

65 | 241 | 205 | 160 | 122 | 26 | 3 | 8-Φ22 |

80 | 283 | 215 | 170 | 138 | 28 | 3 | 8-Φ22 |

100 | 305 | 250 | 200 | 162 | 30 | 3 | 8-Φ26 |

125 | 381 | 295 | 240 | 188 | 34 | 3 | 8-Φ30 |

150 | 403 | 345 | 280 | 218 | 36 | 3 | 8-Φ33 |

200 | 419 | 415 | 345 | 285 | 42 | 3 | 12-Φ36 |

250 | 457 | 470 | 400 | 345 | 46 | 3 | 12-Φ36 |

300 | 502 | 530 | 460 | 410 | 52 | 3 | 16-Φ36 |