設計標準

?技術依據:國標、美標

?設計標準:GB/T12237, ASME B16.34

?結構長度:GB/T12221

?連接法蘭:GB/T 9113 JB 79 ASME B16.5

?試驗與檢驗:GB/ T 26480 API598

性能規范

? 公稱壓力:1.6MPa, 150Lb

? 強度試驗:2.4, 3.0MPa

? 密封試驗:1.8, 2.2MPa

? 氣密封試驗:0.6Mpa

? 閥門主體材料:WCB(C), CF8(P)

CF3(PL), CF8M( R)、CF3M(RL)

? 適用介質:水、蒸汽、油、硝酸類、醋酸類等。

?適用溫度:-29℃-150℃

產品概覽

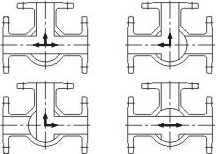

1、氣動三通球閥,三通球閥在結構上采用一體式結構,4側閥座密封式,法蘭連接少,可靠性高,設計實現輕量化

2、三通球閥門使用壽命長、流量大、阻力小

3、三通球閥按作用分單作用和雙作用兩種,單作用型的特點是一旦電源故障,球閥就會在控制系統中國家要求

球閥和閘閥是同一種閥門,不同之處在于它的關閉部分是一個球體,球體圍繞閥體中心線旋轉以開啟和關閉閥門。球閥主要用于管道中用于切斷、分配和改變介質的流動方向。球閥是一種應用廣泛的新型閥門。

產品結構

主要零件材料

| 材料名稱 | 碳鋼 | 不銹鋼 | |

閥體 | WCB | CF8 | CF8M、CF3M |

閥蓋 | WCB | CF8 | CF8M、CF3M |

球體 | 304 | 304 | 316 |

閥桿 | 304 | 304 | 316 |

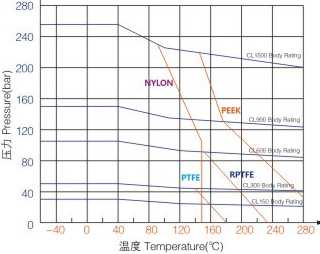

閥座 | PTFE、RPTFE | ||

填料 | PTFE / 柔性石墨 | ||

壓蓋 | WCB | CF8 | |

主要外形尺寸

DN | L | PN16 | D | D1 | D2 | C | N-ΦB | 150LB | D | DI | D2 | C | N-ΦB | 10K | D | D1 | D2 | C | N-ΦB |

15 | 150 | 95 | 65 | 45 | 14 | 4-14 | 90 | 60.3 | 34.9 | 10 | 4-16 | 95 | 70 | 52 | 12 | 4-15 | |||

20 | 160 | 105 | 75 | 55 | 14 | 4-14 | 100 | 69.9 | 42.9 | 10.9 | 4-16 | 100 | 75 | 58 | 14 | 4-15 | |||

25 | 180 | 115 | 85 | 65 | 14 | 4-14 | 110 | 79.4 | 50.8 | 11.6 | 4-16 | 125 | 90 | 70 | 14 | 4-19 | |||

32 | 200 | 135 | 100 | 78 | 16 | 4-18 | 115 | 88.9 | 63.5 | 13.2 | 4-16 | 135 | 100 | 80 | 16 | 4-19 | |||

40 | 220 | 145 | 110 | 85 | 16 | 4-18 | 125 | 98.4 | 73 | 14.7 | 4-16 | 140 | 105 | 85 | 16 | 4-19 | |||

50 | 240 | 160 | 12b | 100 | 16 | 4-18 | 150 | 120.7 | 92.1 | 16.3 | 4-19 | 155 | 120 | 100 | 16 | 4-19 | |||

65 | 260 | 180 | 145 | 120 | 18 | 4-18 | 180 | 139.7 | 104.8 | 17.9 | 4-19 | 175 | 140 | 120 | 18 | 4-19 | |||

80 | 280 | 195 | 160 | 135 | 20 | 8-18 | 190 | 152.4 | 127 | 19.5 | 4-19 | 185 | 150 | 130 | 18 | 8-19 | |||

100 | 320 | 215 | 180 | 155 | 20 | 8-18 | 230 | 190.5 | 157.2 | 24.3 | 8-19 | 210 | 175 | 155 | 18 | 8-19 | |||

125 | 380 | 250 | 210 | 188 | 22 | 8-18 | 255 | 215.9 | 185.7 | 24.3 | 8-19 | 250 | 210 | 182 | 20 | 8-23 | |||

150 | 440 | 285 | 240 | 212 | 22 | 8-22 | 280 | 241.3 | 215.9 | 25.9 | 8-22 | 280 | 240 | 212 | 22 | 8-23 |

主要外形尺寸(高平臺)

DN | L | ISO5211 | TXT | PN16 | D | D1 | D2 | C | N-ΦB | 150IB | D | D1 | D2 | C | N-ΦB | 10K | D | D1 | D2 | C | N-ΦB |

15 | 180 | F03/F04 | 9X9 | 95 | 6S | 45 | 14 | 4-14 | 90 | 60.3 | 34.9 | 10 | 4-16 | 95 | 70 | 52 | 12 | 4-15 | |||

20 | 190 | F03/F04 | 9X9 | 105 | 75 | 55 | 14 | 4-14 | 100 | 69.9 | 42.9 | 10.9 | 4-16 | 100 | 75 | 58 | 14 | 4-15 | |||

25 | 215 | F04/F05 | 11X11 | 115 | 85 | 65 | 14 | 4-14 | 110 | 79.4 | 50.8 | 11.6 | 4-16 | 125 | 90 | 70 | 14 | 4-19 | |||

32 | 230 | F04/F05 | 11X11 | 135 | 100 | 78 | 16 | 4-18 | 115 | 88.9 | 63.5 | 13.2 | 4-16 | 135 | 100 | 80 | 16 | 4-19 | |||

40 | 255 | F05/F07 | 14X14 | 145 | 110 | 85 | 16 | 4-18 | 125 | 98.4 | 73 | 14.7 | 4-16 | 140 | 105 | 85 | 16 | 4-19 | |||

50 | 280 | F07 | 17X17 | 160 | 125 | 100 | 16 | 4-18 | 150 | 120.7 | 92.1 | 16.3 | 4-19 | 155 | 120 | 100 | 16 | 4-19 | |||

65 | 310 | F07 | 17X17 | 180 | 145 | 120 | 18 | 4-18 | 180 | 1397 | 104.8 | 17.9 | 4-19 | 175 | 100 | 120 | 18 | 4-19 | |||

80 | 340 | F07/F10 | 17X17 | 195 | 160 | 135 | 20 | 8-18 | 190 | 152.4 | 127 | 19.5 | 4-19 | 185 | 150 | 130 | 18 | 8-19 | |||

100 | 390 | F07/F10 | 22X22 | 215 | 180 | 155 | 20 | 8-18 | 230 | 190.5 | 1572 | 24.3 | 8-19 | 210 | 175 | 155 | 18 | 8-19 | |||

125 | 380 | 250 | 210 | 188 | 22 | 8-18 | 255 | 215.9 | 185.7 | 24.3 | 8-19 | 250 | 210 | 182 | 20 | 8-23 | |||||

150 | 440 | 285 | 240 | 212 | 22 | 8-22 | 280 | 241.3 | 215.9 | 25.9 | 8-22 | 280 | 240 | 212 | 22 | 8-23 |